A couple of months ago, I was given this splendid setup in return for some data recovery work. The original disc drives had stopped working, and my customer wanted the data from the discs. I used my office BBC B+ to retrieve the data successfully from the discs which were in ADFS format. This equipment – a BBC Master 128, Acorn AKF12 monitor and a pair of 40/80 track disc drives – was in such good condition that I decided to try and get it all working.

The monitor worked fine and the computer booted up quite happily, but the disc drives were definitely in trouble. The right hand one would just about read the first couple of tracks of a disc, but the left hand one wouldn’t read anything at all. I pulled the lid off to see what kind of drives were inside. The disc unit has a ‘Cumana’ label on the front, but they were a dealer and put together boxes with all sorts of drives inside, though usually of good quality.

There’s nothing complicated in there. A simple linear power supply at the back, the two drives, and the switches at the front with some distinctly dodgy-looking wiring. Was zip-tying the 40/80 track switch wiring directly to the 240V mains wiring really such a good idea? And I think I might have splashed out on insulated crimps for the mains connections on the back of the switch.

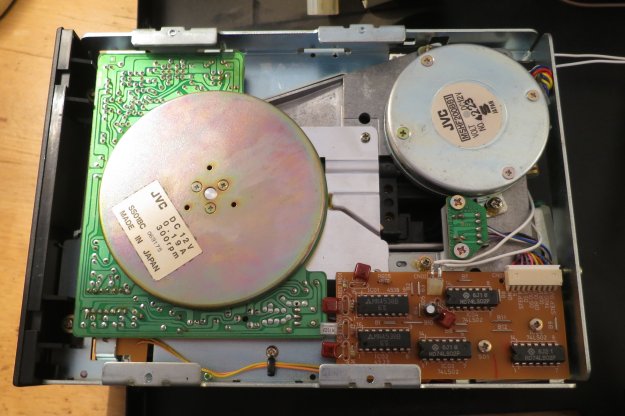

The drives themselves are ones I’d never seen before. They’re made in Japan by JVC, model number MDP-100. I associate JVC with 1980s consumer electronics rather than computer peripherals. They generally had a decent reputation amongst techno-savvy schoolboys. Their video recorders, especially, rebadged in the UK as Ferguson, were almost indestructible. The floppy drives should be worth saving.

Looking more closely at the drives revealed some interesting details. Underneath is a little brown add-on board with a bunch of TTL logic which does the 40/80 track switching. It looks like a factory modification, but the wiring to the main board (not visible in this photo) is a bit heath robinson.

The main board features a couple of 7438 TTL chips made by Tesla in Czechoslovakia. They were definitely a rarity on the western side of the iron curtain. Their date code (courtesy of tubes-store.com) is November 1983, which is the right sort of time. Why on earth would a Japanese disc drive contain Czechoslovak chips? It’s not as if there weren’t any Japanese ones. All the other TTL chips in the drive are made by Hitachi, and they’re 74LS series which was current at the time. Almost nobody was still using straight 74 series in 1983. My best guess is that there was some subtlety of the Shugart-standard floppy disc interface that needed standard TTL, and nobody else was still making it. Or they were just cheap.

The first problem I spotted was corrosion. The board has lots of horrible little electrolytic capacitors on it. The tiny ones like these are notorious for being badly sealed and oozing gunk which causes electrical faults, corrodes tracks and other components. Playing on the safe side, I whipped the lot off and replaced them with newer ones which were a bit bigger, and cleaned up the damage. No tracks seemed to have suffered, fortunately.

Next I inspected the heads. Squinting at them in position, I thought I could see some dirt, so I unscrewed the upper head to get a good look at both of them.

Yuk! I’ve never seen a floppy drive head so dirty. No wonder it wouldn’t read discs. The photo is a view of the upper head. The lower one was just as bad. A thorough scrub with isopropyl alcohol, being careful not to damage the rather delicate suspension, and they came up like new.

I put the upper head back on in roughly the right place and tried the drive again. It would now read discs, at least on the lower head (drive 0) but only intermittently, and wouldn’t work at all beyond track 2. Attempting to get to track 3 or beyond just resulted in a lot of rattling and a disc error.

I suspected a head stepper motor problem. There were two BA6208 chips visible on the PCB between the main JVC controller chip and the connector to the stepper motor, CN04.

I suspected they, or one of them, might be the culprit. This type chip and many similar ones were used for driving motors in lots of consumer electronics, and they did give trouble. I remember replacing them in VCRs and the like. The data sheet is easy enough to find on the internet. A quick check with the scope and sure enough, the right hand one wasn’t working properly. Each chip contains two drivers, and one of them wasn’t driving at all.

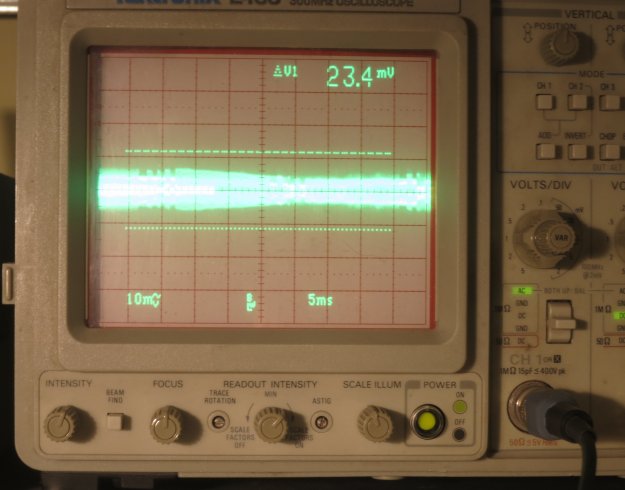

I found a replacement chip for about a pound on allegro.pl. Bargain! I fitted it and now had full head-stepping action. However, reading data still wasn’t reliable. Verifying a known-good disc would fail quite frequently, often in the same place. I had a look at the signal waveform coming from the disc. Fortunately the head amplifier chip, a Hitachi HA16631P, is also documented online. The read data signal is visible at pin 12. What I saw was this.

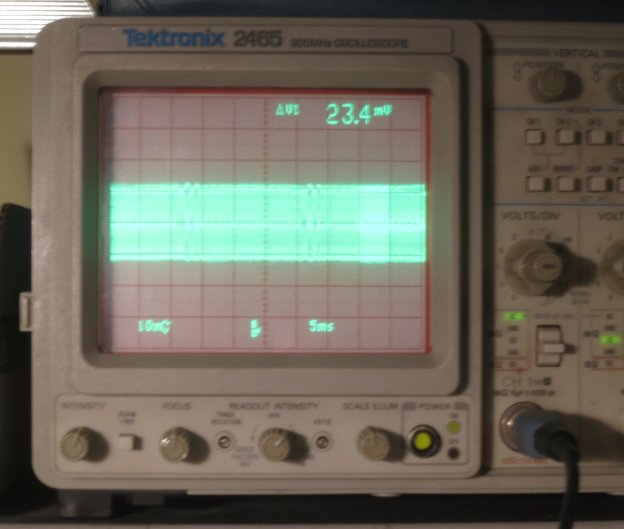

It was difficult to capture on the scope, but basically the waveform is of uneven size: as the disc rotates, it grows and shrinks, sometimes so much that errors result. I tried fiddling with the head alignment by adjusting the head stepper motor, but it didn’t help. Eventually I figured out that during my head-cleaning efforts, I’d managed to bend the thin steel tab which holds the upper head. Not much, but enough to prevent it exerting the right amount of pressure on the disc. This pressure also keeps the disc in contact with the lower head, which is fixed. I straightened it and tried again.

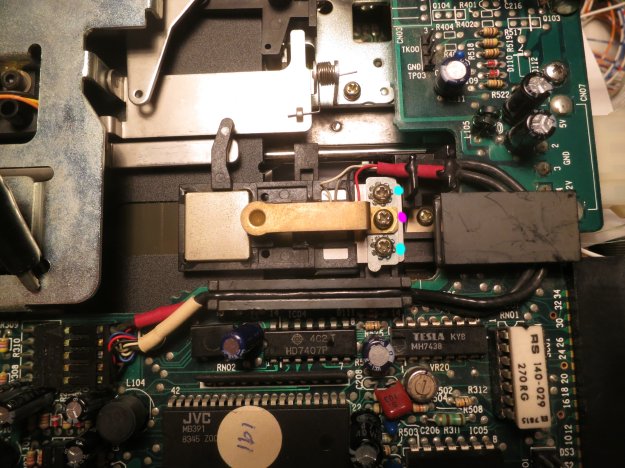

Much better! A nice fat waveform, with no odd variations. You can see the head mounting in the photo below. The two screws marked with a cyan dot mount the head assembly via its steel strip, and loosening them allows it to be aligned with the lower head. The screw between them marked in pink just attaches the copper-coloured bracket which holds a tiny coil spring against the back of the head assembly which adds a little more pressure, though it didn’t seem to make much difference in practice. Perhaps if the disc was wrinkly or something it might help.

After all that I had a disc drive in perfect working order.

At some point I’ll do the second one and then the whole system should be OK.